Electrochromic Systems

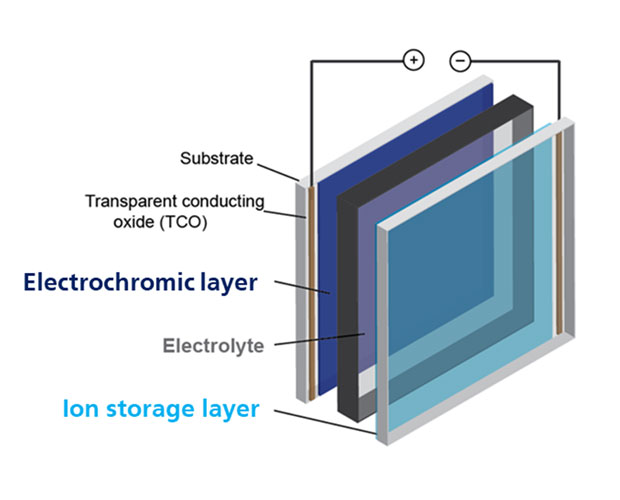

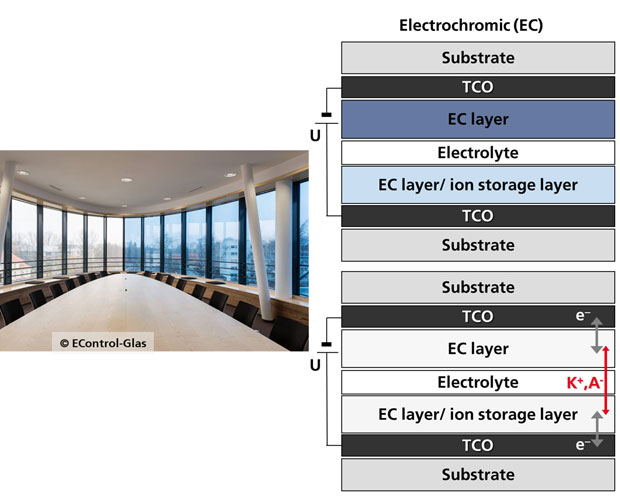

Electrochromic materials, integrated into a layer stack with conductive components, can be automatically switched. By applying an electrical voltage (or current), a charge and ion exchange occurs, leading to the decoloration/coloration of the layers. This effect can be used for light control or window shading, among other applications.

Electrochromic films and systems are particularly suitable for displays, transportation, automotive, and architectural sectors. They offer numerous benefits, including glare protection, control of lighting conditions and interior temperature, as well as energy savings for air conditioning.

We provide solutions and services for customers from various industries in the field of displays, smart film and glazing applications.

Darkening of a window pane with electrochromic film

Switching of a polymeric electrochromic film (time-lapse mode)

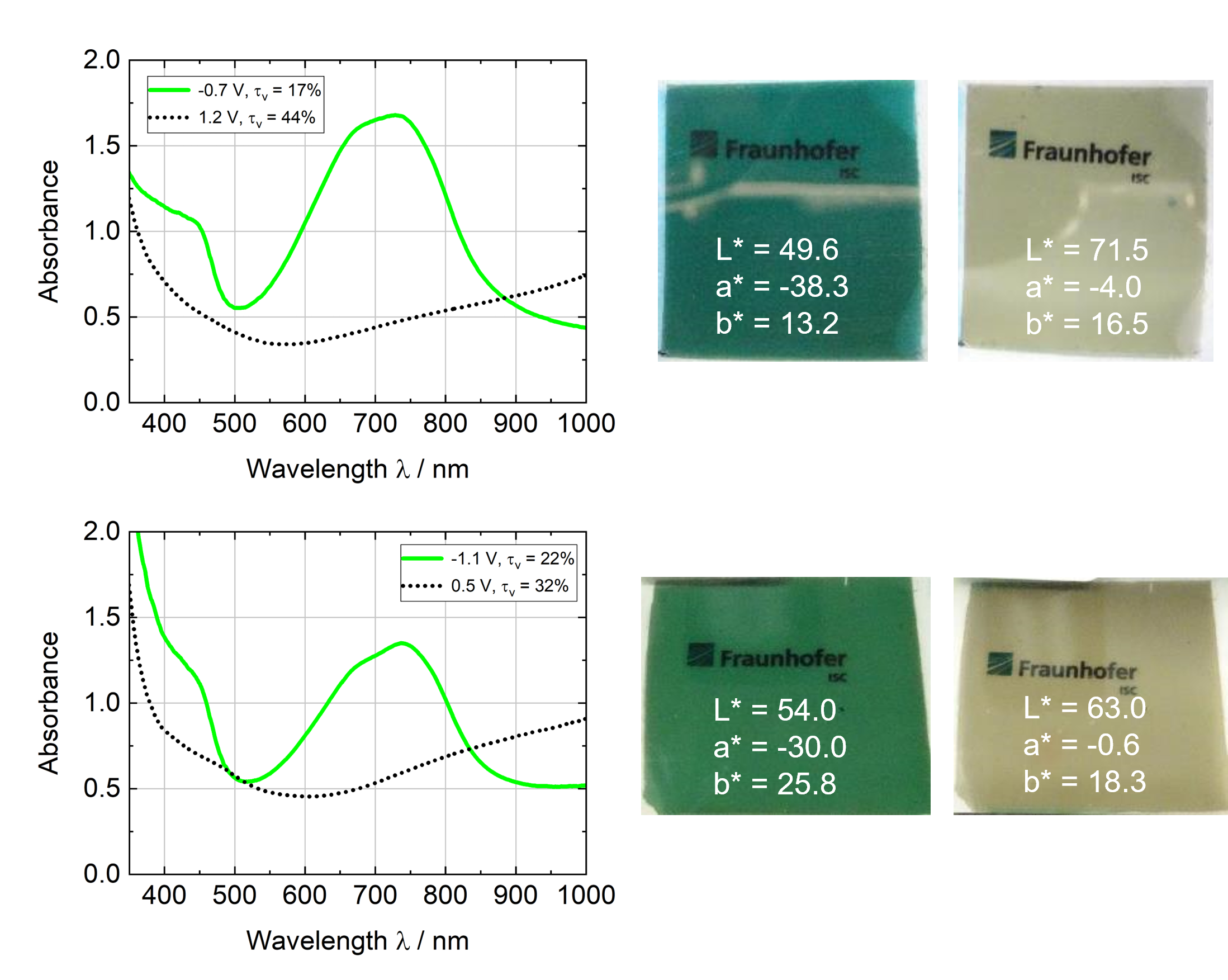

Color change of electrochromic thin-film electrodes

Polymeric electrochromic electrode

Metallopolymeric electrochromic electrode

Electrochromic Materials and Systems - Projects and Publications

You can find out more about the various research tasks and developments in our project examples and publications.

FLEX-G 4.0 project: Retrofittable electrochromic films for windows and glass facades control light incidence

Switchable electrochromic films that darken but remain transparent are expected to achieve this in the future. The fact that this can also be retrofitted in existing buildings is to be demonstrated by the joint project "EnOB: FLEX-G 4.0 - Technologies for innovative switchable films as a retrofit solution for energy-saving windows and glass facades" (funding reference: 03EN1048), funded by the German Federal Ministry of Economic Affairs and Climate Action BMWK.

FLAiM project: Using flexible automation & machine learning to commercialize optic-electronic devices (EC & OLED)

The subject of the German-Canadian joint project FLAiM is the combination of flexible automation, artificial intelligence (AI) and machine learning (ML) to accelerate the development of materials for optoelectronic technologies, such as electrochromic (EC) windows and organic light-emitting diodes (OLEDs).

Electrochemical Devices | Electrochromic Windows

Encyclopedia of Electrochemical Power Sources (Second Edition) / 2024

This chapter provides an overview of electrochromic (EC) glazing technologies available on the market or under development. EC systems for smart windows that are switchable between a colored and a colorless state or between different colored states by applying a low voltage or current can improve energy efficiency and comfort in buildings. Dynamic modulation in the visible (Vis) and near-infrared (NIR) regions of the electromagnetic spectrum enables an adaption of the thermal and optical behavior of a glazing system to ambient conditions. While the energy consumption for air conditioning and artificial lighting is significantly reduced, smart windows can continuously make optimal use of daylight and be tailored to personal needs using appropriate control algorithms.

Electropolymerization of an EDOT-Quinoxaline Monomer for

Green Electrochromic Thin Films and Devices

Polymers / 2024

In this study, we present a 5,8-bis(3,4-ethylenedioxythiophene)quinoxaline monomer with two 4-(octyloxy)phenyl side chains (EDOTPQ) that can be electropolymerized on ITO glass in standard electrolytes containing lithium salts and propylene carbonate as solvent. The electrochemically deposited PEDOTPQ layers show very good adhesion and homogeneity on ITO. The green-colored polymer thin films exhibit promising electrochromic (EC) properties and are interesting for applications such as adaptive camouflage, as well as smart displays, labels, and sensors. Novel organic-inorganic (hybrid) EC cell configurations were realized with Prussian blue (PB) or titanium-vanadium oxide (TiVOx) as ion storage electrodes, showing a highly reversible and fast color change from green to light yellow.

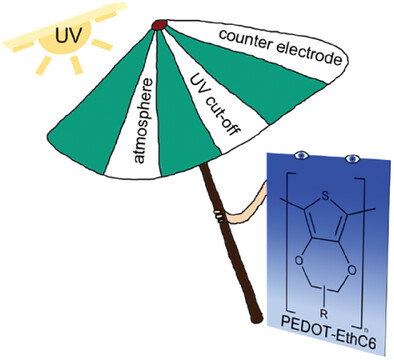

Factors Impacting the Photostability of a Roll-to-Roll Processed PEDOT Derivative for Flexible Electrochromic Devices

Advanced Materials Technologies / 2024

The photostability of roll-to-roll-processed, sidechain-modified poly(3,4-ethylenedioxythiophene) (PEDOT-EthC6) on indium tin oxide coated polyethylene terephthalate (PET-ITO) is improved by excluding ambient atmosphere. In the colored and bleached states, degradation is prevented by 420 and 500 nm long pass filters, respectively. Nickel oxide, as a counter electrode and UV protection, results in ECDs that show no loss of EC performance after 350 h of light exposure.

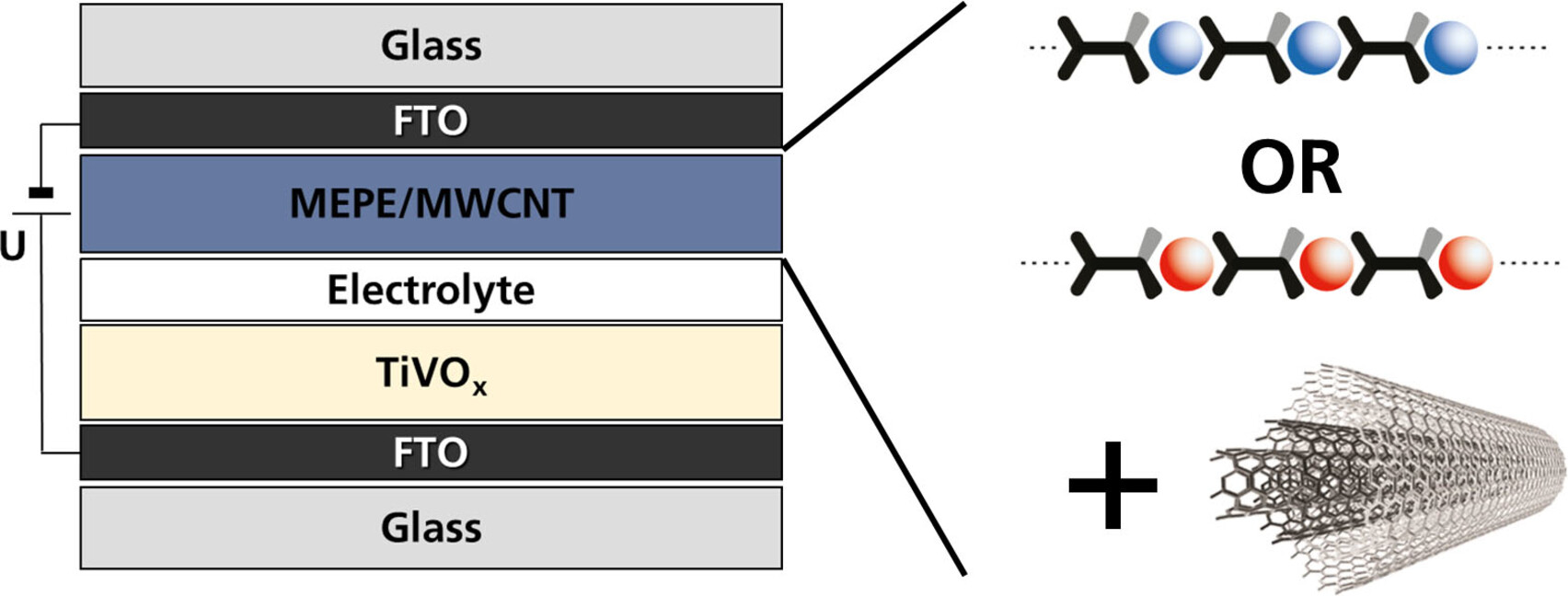

Addition of Multi-walled Carbon Nanotubes to

Fe- and Ru-Metallopolymer Electrodes Enhances

Response Time and Cycling Stability in Electrochromic Cells

ChemElectroChem / 2023

Metallopolymers (MEPEs) show a strong absorption band attributed to a metal-to-ligand charge transfer (MLCT) transition. Fe-MEPE and Ru-MEPE thin films switch reversibly from blue-purple (λmax=584 nm, Fe2+) to colorless (Fe3+) or orange (λmax=518 nm, Ru2+) to pale green (Ru3+). The addition of multi-walled carbon nanotubes (MWCNTs) enhances the electrochromic (EC) properties of Fe- and Ru-MEPE electrodes in several ways: (1) faster response for bleaching/coloring; (2) enhanced Coulombic efficiency; and (3) improved cycling stability, particularly for Ru-MEPE. Moreover, the charge density of the thin film electrodes can be increased upon the addition of the MWCNTs. This performance improvement is demonstrated in electrochromic devices (ECDs) with titanium-doped vanadium oxide (TiVOx) as the optically-passive ion storage layer. The visible light transmittance τv values of the ECDs are improved by the addition of the MWCNTs from 20 %/56 % to 17 %/56 % and from 31 %/47 % and 34 %/55 % in the dark/bright state, for Fe-MEPE and Ru-MEPE, respectively. Thus, the addition of MWCNTs to Fe- or Ru-MEPE is a very promising route for future fast-switching EC applications, e. g., displays, sunroofs, and rear-view mirrors.

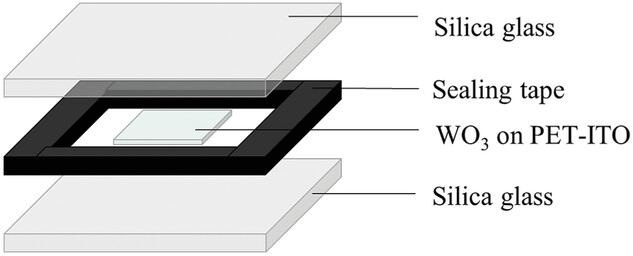

Photochemical Precharging of Tungsten Trioxide for Enhanced Transmittance Modulation in Flexible Electrochromic Devices

Advanced Materials Technologies / 2023

UV irradiation is used to precharge sputtered tungsten trioxide (WO3) on polyethylene terephthalate enhancing the photochromic response with organic solvents. A comparison between the optical and electrochemical properties of photochemically and electrochemically charged WO3 results in a correlation of the transmittance to the respective charge density. This allows for a precise control of the charge density in the precharging process monitored by UV–Vis spectroscopy. A proof-of-concept flexible electrochromic device combining precharged WO3 (charge density: 20 mC cm−2) and Prussian blue (15 mC cm−2) exhibits a superior change in the visible light transmittance (τv) from 8% (dark) to 79% (bleached) and a coloration efficiency of 139 cm2 C−1 at 716 nm.